IDG-STORM is a cloud-based tracking and accounting service for staff and items in real-time.

Fields of application:

- Real-time tracking of personnel, equipment, and technology (RTLS).

- Electronic passport of the product or equipment.

- Access control and management system — ACS.

- Control of work within the same building and at remote sites.

Principle of Operation

ID-GREEN access points collect tag's information within the read zone using directional antennas. The information read from the tags is transmitted in real-time to the IDG-STORM server. The server structures the data and displays them to the user in the form of reports, graphs, and charts. Using any of the antennas connected to the ID-GREEN controller, you can track both a group of tags and a single tag in real-time.

System Objects:

- Tag — UHF RFID Tag attached to the Item. (more about Tags).

- Item — the minimum accounting unit of the system (helmet, key, pump, container) with tags. Several Tags on the Item improve the quality of information.

- Employee — a system accounting unit, a person (visitor, surveyor, miner, factory worker), Item owner. Several Items assigned to the Employee improve the quality of information.

- Zone — a logical object in a system that corresponds to space in the real world (warehouse, walk-through, production zone).

An object in the system corresponds to an object in the real world. Accounting and control are based on the objects and events of the system: The helmet, jacket, and boots of John Doe left Zone A and appeared in Zone B.

Example №1. Counting miners in a mining zone

Conditions.

The object for the ID-Green solution is a mine with one lamp and one production zone.

At the beginning of the shift, the miners enter the lamp room, where they take personal helmets

with flashlights and descend into the production zone. At the end of the shift, the miners rise and leave their

helmets and lights in the lamp room.

Goal.

Find out who is in the mining zone in real-time and generate a report on the time spent in the mining zone for each miner.

Solution Steps

- 1. Each lamp is equipped with a UHF RFID tag.

- 2. At the exit from the lamp and in the production zone, one antenna is installed.

-

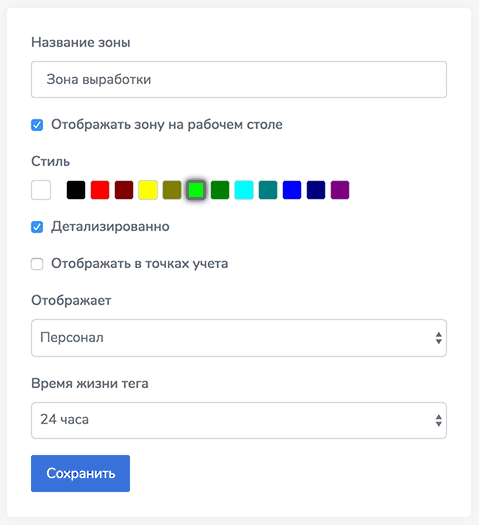

3. The zones corresponding to the lamp and production zones are added to the system.

-

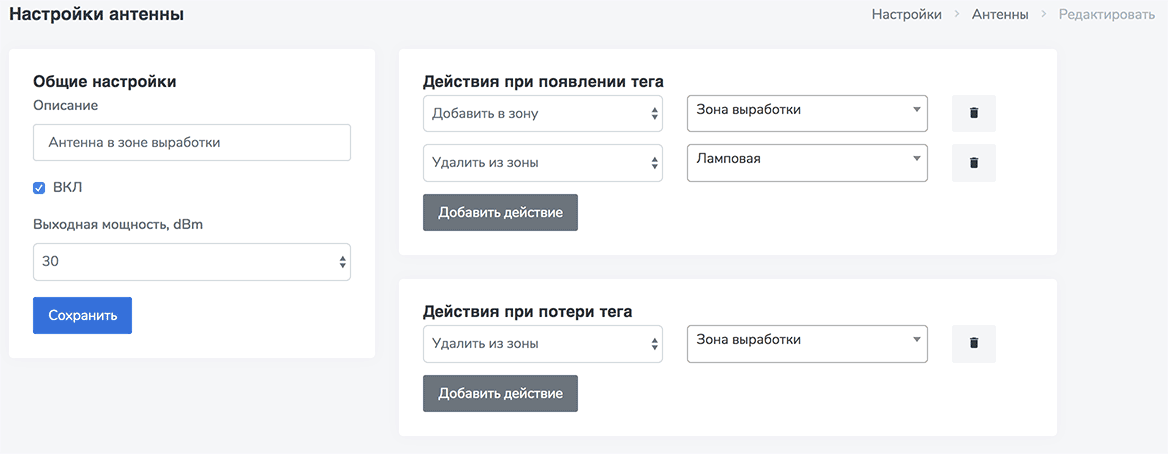

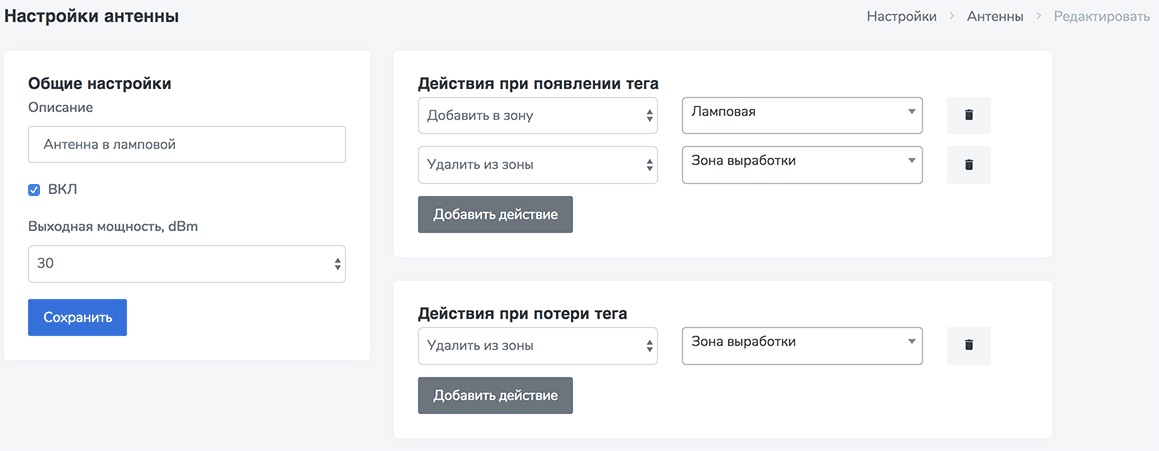

4. Actions for antennas are assigned.

If a miner is detected by an antenna near the lamp, then it is counted that he left the mine.

-

5. During operation, the system accumulates data on the presence of miners in the zones.

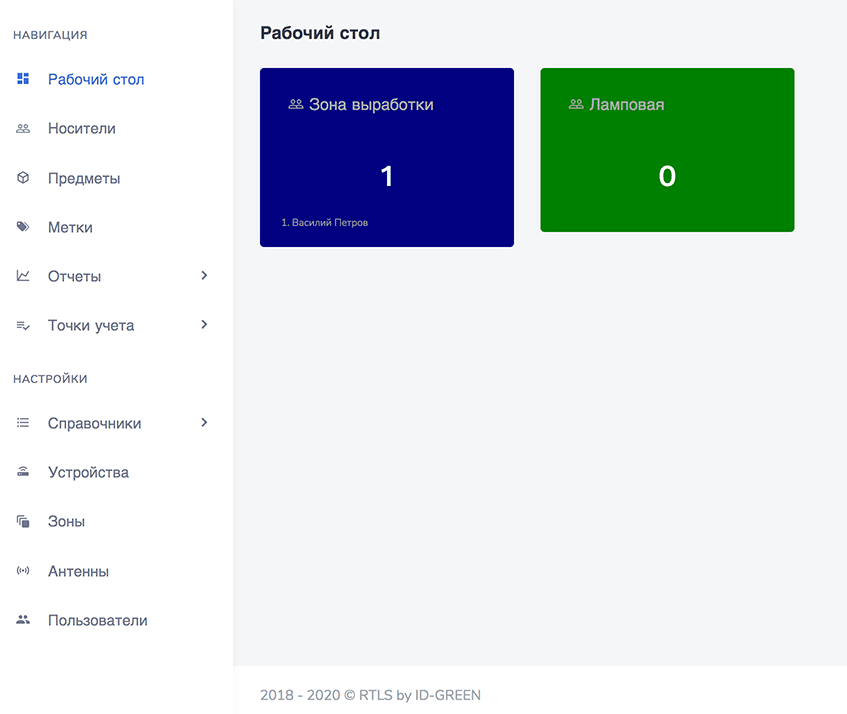

Dashboard:

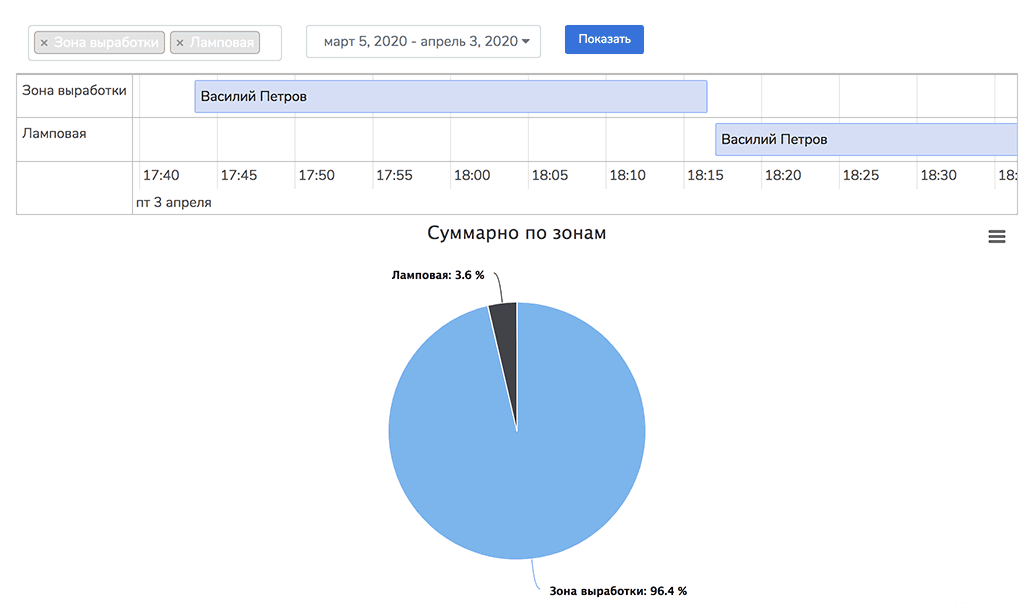

Zone move history report: